MWZ-1650GC fully automatic die cutting machine with full stripping

------ with Cassette feeder

Model: MWZ-1650GC,

Machine: fully automatic flatbed die cutting machine with full stripping system and Italy cassette feeder;

Specification

Max.sheet Size | 1650×1200mm |

Min.sheet Size | 650×550mm |

Max.Die-Cutting Size | 1630×1180mm |

Max.Mechanical Speed | 5500s/h (depend on die and sheet’s conditions) |

Min.gripper waste | 10mm |

cutting rule height: | 23.8mm |

die cutting precision: | ± 0.5mm |

electrical Power | 380V.50HZ, 3-Phase |

Max.Die-Cutting Pressure | 450tons |

Gross Weight | 38000KGS |

pressure adjusting range: | ± 1.5mm |

stock range | E.B.C.A and AB flute corrugated board ≤ 9mm |

Inner chase size | 1660x1210mm |

dimension | 11200x5560x2550mm( include working platform) |

Power & Air Infomation

Total power required | 37KW |

Main motor power | 18.5KW |

Air compressor | 1.05 m3/min |

Quality of machine detail

1.Feeder

![]()

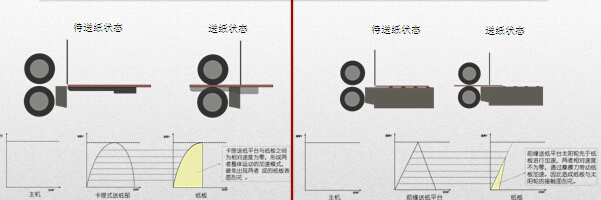

--- pure Italy import Cassette feeder to ensure machine feed stable and long life using.

--- Vector “ zero point” feeding to be high precision ±0.05 mm

Cassette Feeder Lead edge Feeder

--- sheet on the case to move without friction between sheet and case to ensure 100% solve Scratch problem

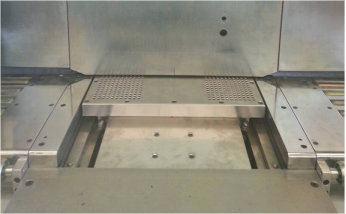

2. Die Cutting Section

--- Operation die cutting section by touch screen to ensure working efficiency and easy operation

--- Centre line system reduce time of installation die

--- Duty heavy die plate to ensure long using and reduce production cost. Above die plate thickness is 2mm can easy replace next orders to save time

--- Air cushion underneath the die plate for easy sliding

--- Pneumatic lock system for die chase frame and handle locked the plate to ensure 100% safty and fastness locked

--- Die moving plateform adopts worm and gear with whole sealing lubrication system to ensure pressure balance and clean oil system.

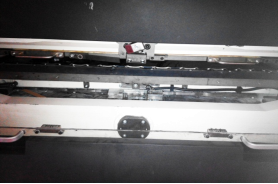

3. Stripping Section

--- adopts 2 frame (male and female) stripping plate system which is very suit for thickness corrugated sheet

--- Center line system can ensure fast set up and change over stripping plate to be high working efficiency ,this device also can install stripping plate at outside.

--- One button Motorized upper stripping frame increases the operation space and easy fix stripping plate.

--- Gripper bar register block at outlets of stripping station ensures the accuracy of stripping

--- Full stripping with / without lead edge waste stripping convertible by one button , no tool change, more operator friendly and safe operation

--- Second stripping device can removal front edge waste and transfer it outside machine by conveyor belt

4. Delivery Section

--- Adopt non-stop automatic delivery system and safety photoelectric device to ensure paper delivery in good order and convenient paper pile transfer

--- Motorized upper frame suspending hoister

--- Counter can set based on your products stack request , which will be improve working efficiency.

--- Big air cylinder be sure fork lift strong and quickly

--- Spring loaded adjustable chain tensioner for maintaining constant tension thus reducing stress on chains and producing smooth gripper bar movement